Filament is not coming out of the nozzle

Video Tutorial:

Detailed Description:

When filament is not coming out of the nozzle, the nozzle may be clogged.

You have three good options for clearing a clogged nozzle:

1. You can pull the clog out of the nozzle using the “soft pull” method

2. You can “floss” the clog out of the nozzle using a nozzle cleaner.

3. You can heat the nozzle and push the clog through the nozzle.

[Pro Tip: Do NOT remove the nozzle or disassemble the hot end of the

printer when you have a clog. Instead, try these three options. If they

don’t fix the problem, complete a troubleshooting request and our

Service Team will help you.]

[Pro Tip #2 : Never leave your printer nozzle at build

temperature (220°C) while the printer is idle. The melted

plastic remaining in the nozzle will “bake” onto the nozzle and

become a hard carbon blockage.]

1. Try to pull the clog out of the nozzle using the “soft pull” method:

a. Turn the machine on, select Setup > Preheat soft pull, and wait until

the temperature reaches 100°C.

b. When the nozzle temperature stabilizes at 100°C, squeeze the

extruder release lever with one hand and pull the filament out of the

extruder with your other hand with a steady, even force.

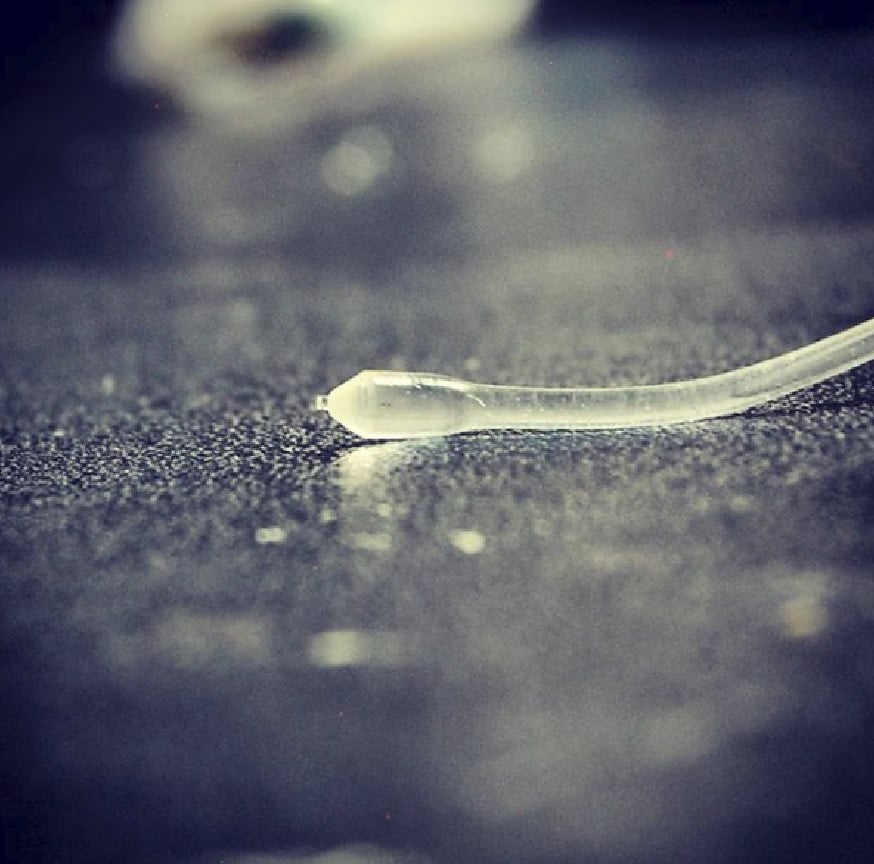

c. Inspect the end of the filament. If the end of the filament has the

shape of interior of the nozzle—a thicker cone-shaped plug—you

have successfully pulled all of the filament out of the nozzle,

including the clog.

d. If the clog did not clear using the “soft pull” method, clip the melted

end of the filament off, reload it, and select Setup > Cooldown and

wait five minutes for the hot end to cool down. Then repeat the soft

pull process.

Soft Pull Example:

[Pro Tip : Every time you change filament on your 3D printer,

remove the filament with the nozzle at around 100°C. This

“soft pull” method usually removes all the old color of filament

from the hot end, so when you begin printing again, the new

color will begin printing immediately.]

2. Use a nozzle cleaner to clear the nozzle:

a. Remove the filament using the “soft pull” method.

b. Select Setup > Preheat PLA. Wait for the nozzle to reach the set

temperature of 220°C for PLA.

c. Raise the Z axis carriage by selecting Controls > Move axis > Move

1mm > Move Z and spinning the knob. (You can also manually rotate

the leadscrew to move the gantry up.)

d. When the nozzle has reached 220°C, use pliers to carefully insert the

nozzle cleaner up into the tip of the nozzle. IT IS VERY HOT, SO BE

CAREFUL NOT TO BURN YOURSELF!

e. Squeeze the extruder release lever with one hand and push the

filament into the extruder manually.

f. Alternate “flossing” with the nozzle cleaner and pushing the filament

through the extruder until a consistent bead of filament is extruded

through the nozzle.

3. Try to push the clog through the nozzle:

a. Select Setup > Preheat PLA. Wait for the nozzle to reach the set

temperature of 220°C for PLA.

b. When the nozzle has reached 220°C, squeeze the extruder release

lever and load the filament. When the filament would normally stop,

keep pushing to manually push the filament out of the hot end

nozzle of the extruder assembly.

c. Watch the filament to ensure it is not curling as it comes out of the

nozzle. After pushing several inches of filament through, it should be

going relatively straight. If it isn’t, turn off the printer and do

another soft pull (step a)